Plastic injection molding has its roots in the 1800s. Today it’s still the most popular way to manufacture plastic parts.

Of course, the process has changed a lot in the last 150 years. Advanced techniques allow manufacturers to quickly create precise molds with little waste.

Most people use injection molded products every day. Despite this, the process has yet to be well understood by the public. This essay explains “what is plastic injection molding” and discusses why it is the preferred choice for creating plastic goods.

Injection Molding History

Inventors J.S. and J.W. Hyatt patented the first plastic injection molding machine in 1872. The first injection-molded products were cellulose pool balls.

These plastic balls replaced the ivory ones that were standard in the 1800s. Hyatt’s machine used a plunger system to force cellulose into a mold.

In 1946 James Hendry pioneered the next big advance in injection molding tools. He patented a machine that used an auger instead of a plunger to inject material into the mold. This new machine allowed for faster production times, and now almost all injection molding uses his auger system.

What is Plastic Injection Molding?

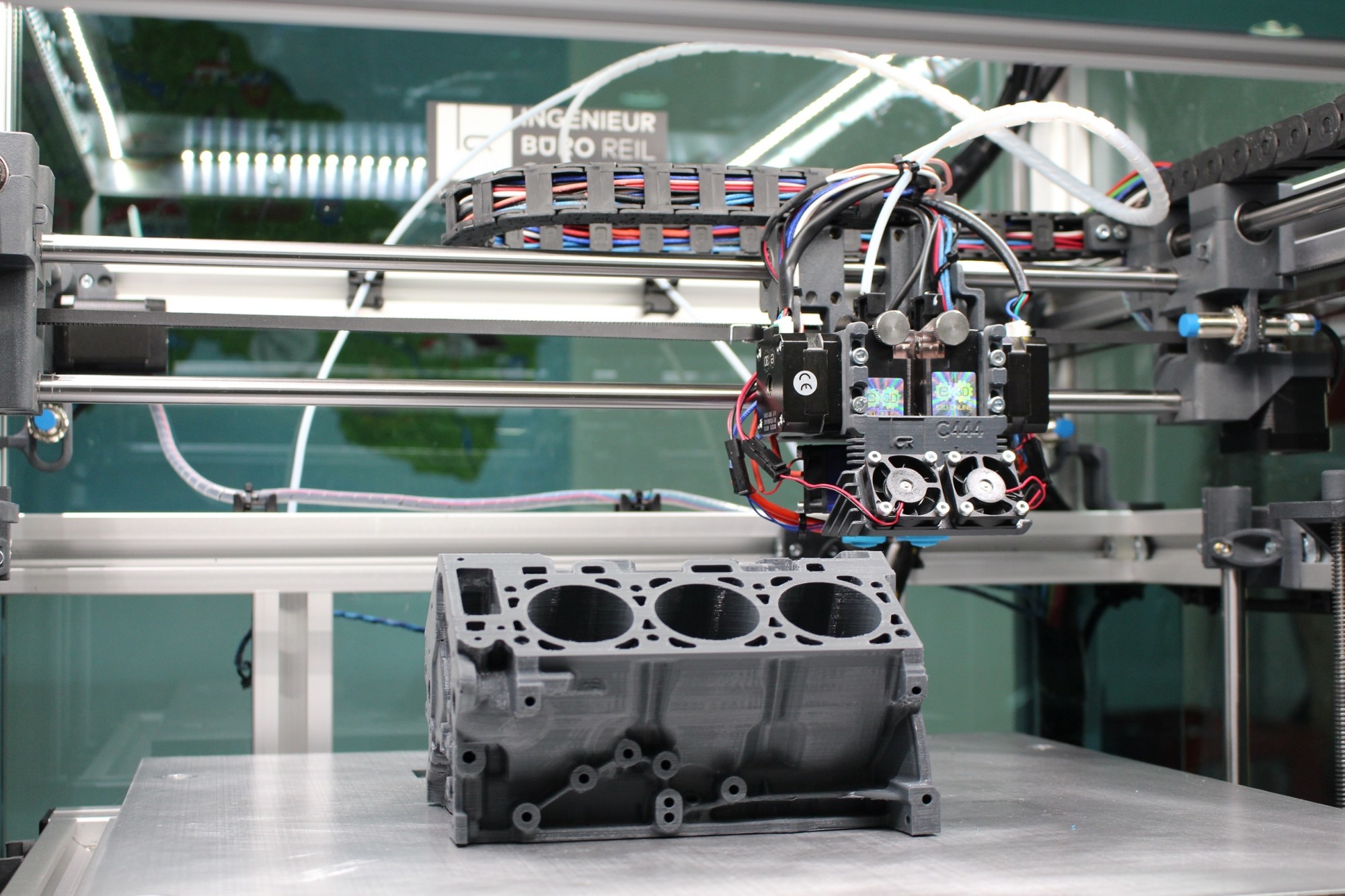

Plastic injection molding involves using pressure to force melted polymers into a custom-designed mold. Then, plastic is then separated from the mold and allowed to cool. Sometimes manufacturers use techniques like overmolding to make complex shapes in multiple steps.

Plastic Injection Molding Parts

The polymers used for molding start as small pellets. Then, these pellets are stored in a hopper that feeds them into the auger.

The screw inside the auger forces the pellets toward the mold. The heat generated by friction from the screw’s rotation melts the pellets as they travel towards the mold.

A gate lets enough plastic into the mold to thoroughly coat it. Therefore, more plastic gets injected into the mold as it cools to prevent shrinkage. Next, the finished product goes through a final cooling process to be ready for use.

Injection Molding Plastic Types

Most types of polymer can be injection molded. Plastic, rubber, and biodegradable materials all excel in the injection molding process.

Special processes like overmolding can create injection-molded objects from multiple materials at once. This is useful in automotive applications where it may be desirable to cover a hard plastic car interior component with softer rubber, for example.

Custom Injection Molding Solutions

Injection molding offers unmatched flexibility and precision compared to other manufacturing techniques. With injection molding, you can create a limitless variety of customizable shapes. Therefore, making the process less expensive than other types of plastic molding.

So, if you think injection molding is the right option for your company, contact Nova Stevensville today.